gtxracer2

180 header nutcase

- Joined

- Sep 17, 2020

- Member Number

- 2885

- Messages

- 48

Hi all - this is a continuation of my thread over on the other bulletin board. You can find the old thread here. This came from a request in this thread.

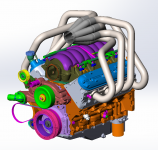

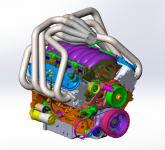

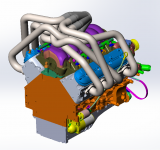

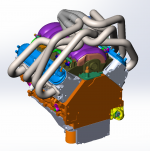

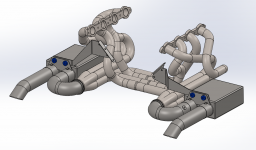

I'll start off from March 2020, where I had just finished the design of the 180 degree headers for this build. It's a 1999 Porsche 911 (996 variant for P car enthusiasts) and a 1999 GM LS1 from a Camaro. It's running a Terminator X kit at this time with drive by cable (DBC) throttle body. I also converted the car from the automatic Tiptronic (gross) to the 6 speed manual with limited slip (how they all should be). I also had to plumb my own hydraulic lines as the Porsche hydraulic lines were routed through the cab and it was a series of 12+ lines. I used two lines and bulkhead fittings in stainless which cost a lot less, looks better, and is less prone to leaks and trapped air.

I'll be copying and pasting a few of the posts here and then I'll get this thread up to date. It looks like most of you left off when I was putting in the electric power steering, so here goes:

__________________________________

The 180 degree headers have been ordered. I should see the first set in about 3 weeks. I threw on the bumper to measure for exhaust outlets, muffler placement, etc.. I think the Spintech mufflers should sound pretty good!

Maybe I should paint or coat the pan after all…

I threw in a new AGM Oreilly's battery and it CRANKS! No fuel pressure but it turns over great. I need to verify a few things, such as oil pressure and fuel pump operation before firing. I have some freebie LS truck exhaust manifolds on there for now.

Nearing the end of the electric steering conversion. I used RSR fittings since I didn't have time to make my own. They're a nice set for only $90. I also bought new Porsche O-rings made from organic unicorn toenails for too much money. I'm using PTFE 6AN lines and fittings (5/16 ID) for pressure with 6AN rubber hoses for return (3/8 ID). I have bought some nice bulkhead fittings and will run the lines near the brake master and pass through the firewall. Easy peezy.

Placement of the new pump. Way too tall. Bracket not really usable. I don’t want to drill down into the area it’s sitting on, that’s the fuel tank. More on how I mount this later on!

New bracket I drew up:

Cut on the Langmuir baby plasma cnc and bent:

I drew up this bracket. It needs a couple tweaks but came out great for a first draft. These TRW pumps are from a Vauxhall Astra and is the same pump as the Porsche GT3 cup pumps....but costs 1/10 of the price. As soon as I feel like sitting on my side for another 3 hours putting in the bolt on the rack that holds the fittings, I'll have this wrapped up.

Mega extension to reach said bolt, which stripped, but I got it out:

RSR Fittings and new SS bolt: Rebel S Racing (RSR) Steering Rack Fittings for elec. Pump – John James Racing

To do list is much shorter now:

Find lack of fuel pressure culprit and fix

Shift cables were wrong end type for transaxle end; too large, need earlier smaller versions or convert to heims

Fill and bleed coolant

Fill and bleed brakes

Bleed clutch

Tweak throttle cable; Only opens 75%

Mount Terminator ECU

Run Terminator lines permanently and route through interior

Reassemble interior

Tweak clutch pedal; it’s slightly out of position

Fab intake tube and tap for MAT sensor

Fab/buy PCV catch can

Hookup Porsche oil pressure sensor; extend wiring harness

Extend starter wire

Rework starter to alternator positive cable; route in cleaner fashion

Add 1 more block to chassis ground

Clean up wiring routes through car

Reassemble rest of the rear end of the car; crossmembers, sway bar, bumper, etc.

Final cut/fit of engine lid area

Test Drive!

I'll start off from March 2020, where I had just finished the design of the 180 degree headers for this build. It's a 1999 Porsche 911 (996 variant for P car enthusiasts) and a 1999 GM LS1 from a Camaro. It's running a Terminator X kit at this time with drive by cable (DBC) throttle body. I also converted the car from the automatic Tiptronic (gross) to the 6 speed manual with limited slip (how they all should be). I also had to plumb my own hydraulic lines as the Porsche hydraulic lines were routed through the cab and it was a series of 12+ lines. I used two lines and bulkhead fittings in stainless which cost a lot less, looks better, and is less prone to leaks and trapped air.

I'll be copying and pasting a few of the posts here and then I'll get this thread up to date. It looks like most of you left off when I was putting in the electric power steering, so here goes:

__________________________________

The 180 degree headers have been ordered. I should see the first set in about 3 weeks. I threw on the bumper to measure for exhaust outlets, muffler placement, etc.. I think the Spintech mufflers should sound pretty good!

Maybe I should paint or coat the pan after all…

I threw in a new AGM Oreilly's battery and it CRANKS! No fuel pressure but it turns over great. I need to verify a few things, such as oil pressure and fuel pump operation before firing. I have some freebie LS truck exhaust manifolds on there for now.

Nearing the end of the electric steering conversion. I used RSR fittings since I didn't have time to make my own. They're a nice set for only $90. I also bought new Porsche O-rings made from organic unicorn toenails for too much money. I'm using PTFE 6AN lines and fittings (5/16 ID) for pressure with 6AN rubber hoses for return (3/8 ID). I have bought some nice bulkhead fittings and will run the lines near the brake master and pass through the firewall. Easy peezy.

Placement of the new pump. Way too tall. Bracket not really usable. I don’t want to drill down into the area it’s sitting on, that’s the fuel tank. More on how I mount this later on!

New bracket I drew up:

Cut on the Langmuir baby plasma cnc and bent:

I drew up this bracket. It needs a couple tweaks but came out great for a first draft. These TRW pumps are from a Vauxhall Astra and is the same pump as the Porsche GT3 cup pumps....but costs 1/10 of the price. As soon as I feel like sitting on my side for another 3 hours putting in the bolt on the rack that holds the fittings, I'll have this wrapped up.

Mega extension to reach said bolt, which stripped, but I got it out:

RSR Fittings and new SS bolt: Rebel S Racing (RSR) Steering Rack Fittings for elec. Pump – John James Racing

To do list is much shorter now:

Find lack of fuel pressure culprit and fix

Shift cables were wrong end type for transaxle end; too large, need earlier smaller versions or convert to heims

Fill and bleed coolant

Fill and bleed brakes

Bleed clutch

Tweak throttle cable; Only opens 75%

Mount Terminator ECU

Run Terminator lines permanently and route through interior

Reassemble interior

Tweak clutch pedal; it’s slightly out of position

Fab intake tube and tap for MAT sensor

Fab/buy PCV catch can

Hookup Porsche oil pressure sensor; extend wiring harness

Extend starter wire

Rework starter to alternator positive cable; route in cleaner fashion

Add 1 more block to chassis ground

Clean up wiring routes through car

Reassemble rest of the rear end of the car; crossmembers, sway bar, bumper, etc.

Final cut/fit of engine lid area

Test Drive!

thanks everyone! I have a few more updates coming down the pipe.

thanks everyone! I have a few more updates coming down the pipe.