boardbysled

Well-known member

Time to bring this thread back up to speed.

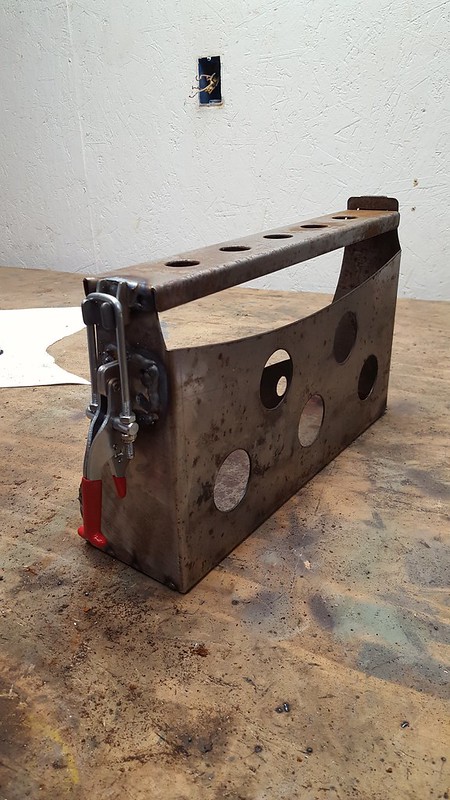

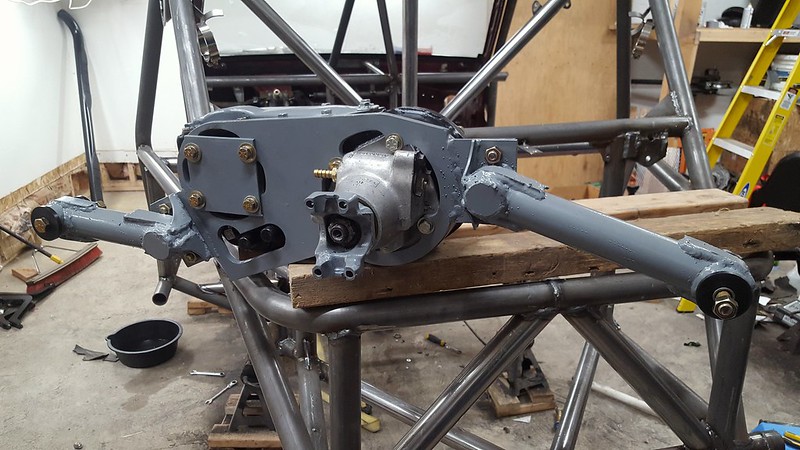

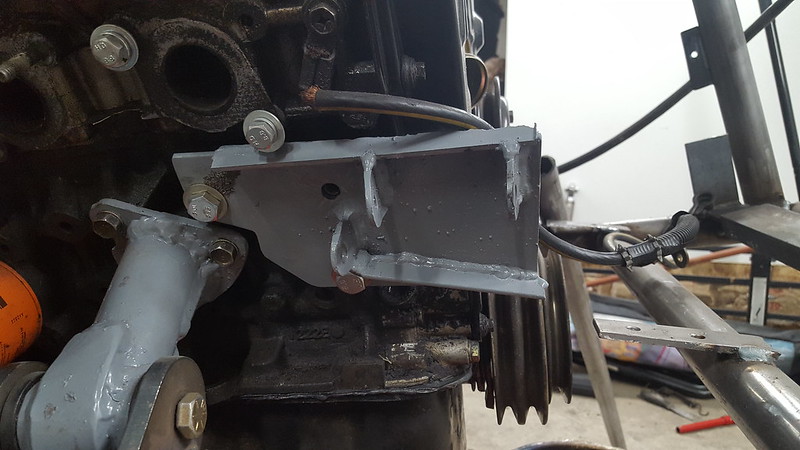

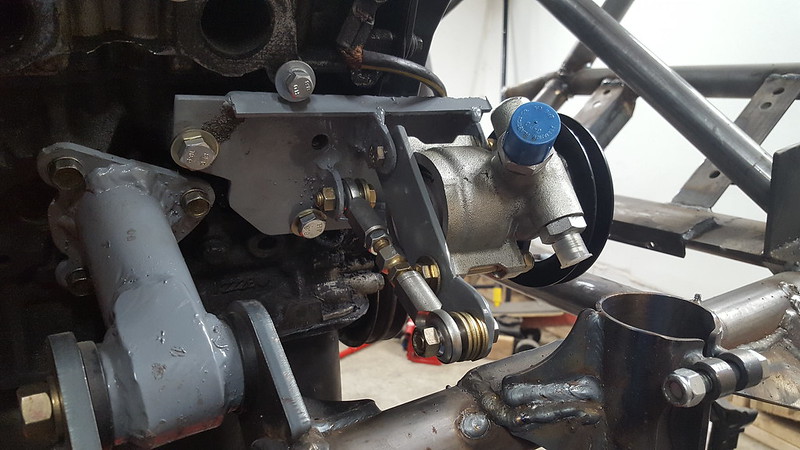

Got the transfer case mount mocked up. Had the D300 mounting plate cut locally. Plan on making a plate over the front output cover plate to stiffen it up.

IMG_20180722_163242_969_zpscnpojok5 by boardbysled, on Flickr

IMG_20180722_163242_969_zpscnpojok5 by boardbysled, on Flickr

Got the transfer case mount mocked up. Had the D300 mounting plate cut locally. Plan on making a plate over the front output cover plate to stiffen it up.

IMG_20180722_163242_969_zpscnpojok5 by boardbysled, on Flickr

IMG_20180722_163242_969_zpscnpojok5 by boardbysled, on Flickr