[486]

ugh, that guy again?

haha I could be your wife

years of vehicle inspections have inured a sense of pessimism to my outlook

years of vehicle inspections have inured a sense of pessimism to my outlook

it's great, until i mis-diagnose something and get to hear "See?! I knew it was [whatever she said originally that was actually broke]"haha I could be your wife

years of vehicle inspections have inured a sense of pessimism to my outlook

my gf has only asked one thingshe certainly knows enough to find all the issues

getting her to see any positive is the hard part

my gf has only asked one thing

How much is it going to cost to paint it...i told her 10 grand. its not...not true.

heaven forbid we remember weaving styles by location

heaven forbid we remember weaving styles by location  ) to replace the likely couple decades old cheap black cover, which is hiding the taped together actual seat cover.

) to replace the likely couple decades old cheap black cover, which is hiding the taped together actual seat cover.yeah i've seen the standard new kits that come with all the stuff.You can buy a new upholstery kit for for that for 250-300 and hog ring it yourself, that's my plan.

IIRC MT4Runner or something had a pretty nice cheap paint thread on the dark side

I used a $130 gallon kit from Amazon and a $40 spray gun and did good enough for one of my trucks. I'll be doing it again. Where I lacked skill, technique, and expensive materials, my prep work carried me and came out halfway decent. The pros are right, prep is everything

I was thinking today about doing it in sections, I dunno.

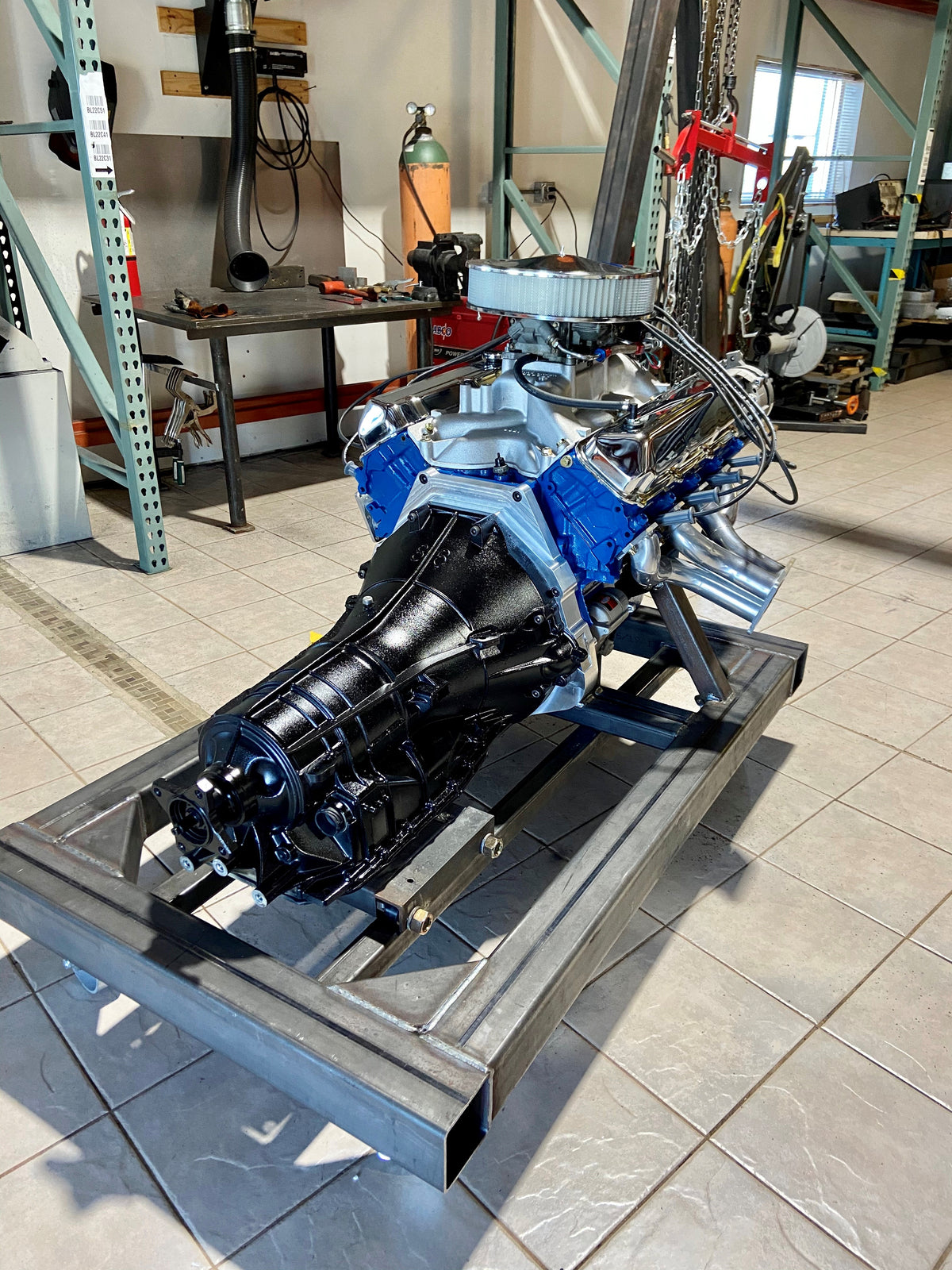

I was thinking today about doing it in sections, I dunno.Ford 3-Speed Auto - Gearvendors

Looks like it would net:

1st: 2.46

2nd: 1.46

3rd: 1:00

OD: 0.78

VS

E4OD/4R100

E4OD and 4R100 Control and Swap Info (usshift.com)

1st: 2.71

2nd: 1.54

3rd: 1:00

OD: 0.71

6R80 Ratios

1st: 4.17

2nd: 2.34

3rd: 1.52

4th: 1.14

5th: 0.87

6th: 0.69

the "granny gear" first gives the benefit of being more close to being able to drop the rear end ratio, say 4.1 to 3.5 for still easier takeoff under load from a stop and even lower cruise speeds.

alright, i need to put that out of my mind for a bit

gearstar.com

gearstar.com

| First | 2.48 |

| Second | 1.48 |

| Third | 1.00 |

| Fourth | 0.75 |

transmissionadapters.com

transmissionadapters.com

The AOD looks good on paper but there's a reason nobody runs it and its electronic derivative in any truck that isn't a hot rod. It's simply not durable enough for what you will be doing.Adding these two to the list:

4R70W (AOD)

looking at the comparison pictures for the "quick 2" makes the 4R70W look like a good option with s smaller body than everything else, and apparently the same 500ish HP "stock rating"

damn.The AOD looks good on paper but there's a reason nobody runs it and its electronic derivative in any truck that isn't a hot rod. It's simply not durable enough for what you will be doing.

It might handle 500hp just fine in a mustang, it might tolerate life just fine behind a 302 in a Bronco. It has no place behind a 400 in a 3/4 ton truck that will probably tow shit from time to time.

and you're probably right that it would just shit shafts or something stupid.

and you're probably right that it would just shit shafts or something stupid.

i grenaded a couple manuals trans.....in my toyotai had a aode in a 96 f150 302 2wd. and i grenaded 6 of them in 6 years.

They are terrible. Dont.

My dads 97 f150 has a e4od and north of 500k miles and it had a hard life..very hard life.

ive broken 1 e4od, i liked to torque over my idi power stalling it, and i broke the piece that locks it into gear, unfortunately its like the first thing to go in the case during a rebuild.

ive had service trucks with 4r100 and a 6l90e and couldnt kill those.

ive never killed a manual though

yeah trying to find a medium/heavy weight fabric that is woven is not easy at the store, found some interesting patterns on the internet and ordered some swatches because it is even more difficult to do online. There is apparently a standardized rating system called "double rub" for abrasion resistance, with these swatches i'll at least get an idea of what 9k - 15k double rubs look like. really i just need a loom of my own and a few years of experience so that i can make my own whatevers.when you got the seat apart, toss some of those thin rubber '90s chevy floormats between the foam and the springs

the foam sinks through the wires over time otherwise

ETA: a lot of those fabrics look like they'd be a torn mess pretty quick

good to know, I'm not planning on leaving it there fulltime. always wanted one, never had one, this thing smells toxic and could be many things so i'm curious what it is at currently, then I can use it to see what happens futzing with the replacement carb.don't run the wideband sensor in the exhaust without it being powered on

it'll die quick

they generally die quick anyways, so don't be shocked if you go through sensors fairly often

#7 · Mar 23, 2006

These springs are the last thing you should try and tune. In many cases you will not be able to tell a difference. Edelbrock only recommends changing them to address "driveability" issues.

I don't know where this idea comes from, but these springs have absolutely no relationship to idle vacuum anymore than a power valve in a Holley does. Idle runs entirely off of the idle circuit and these rods affect only the primary main circuit. The idle circuit may actually draw fuel from the same well as the primary circuit, but the fuel restrictions (read: jet sizes) are radically different with the main being much much larger than the idle no matter what rod step you are on.

If you hooked up a wide band O2 AFR meter what you would see is that as vacuum progressively drops so does the amount of fuel. Thus the engine goes leaner. At some point you hit the needle/spring threshold and you get an extra amount of fuel. Thus you might think of the AFR as a couple of sawtooth notches. You want to tune such that the bottom of the notches stay at 14.7 or above. For best economy you want to jet/rod to get as close to that 14.7 as you can. More fuel than that at cruise is just a waste.

Personally I have a theory that these springs actually compensate for the idle/transition circuit turning on/off. When the manifold vacuum drops to a point around 5-7" the Edelbrock idle/transition circuit shuts off. This is by design and controlled by the relative sizes of the fuel restriction and air bleeds. At this point you need extra fuel from the primary main circuit to compensate. Note that this has nothing to do with the motor and it's vacuum level, it is all about the Edelbrock idle circuit air bleed sizes.

Edelbrock technical documents claim the piston/rod compensates for load. Maybe, but if I really want to load the engine I am going to open the secondaries. So that is where I want to put my major extra load compensation fuel and drive the AFR towards 12.5.

Also it seems to me that if you idle at a fairly high RPM and at only 8" then either you have a serious cam in that motor or your ignition is not setup correctly at idle. Maybe a combination of both. My 402 with an HR296 used to idle at 850 with around that vacuum level, until I put in the right vacuum advance and hooked it up to manifold vacuum. Now it idles around 11" with 30* advance at idle, 18* basic initial plus 12* vacuum advance.

Dont assume that. The carb i pulled off the engine had damage so i gave you the one from in the barn. That means last time it was used it was mounted to a turbo...so..with it ebing leaned out and then being mounted to a turbo as a suck through probably means 1 of 2 things.considering the 1406 came from a running ford 400, safe to assume that it has already been "tuned" and what appears to be leaned out far from stock. (3 stages lean cruise, 1-1/2 stafe lean power, 1 \

sorry, what I had meant by tuned was "not stock" jets that they ship with. thanks for clarifying, which you probably did before. I'm not trying to pretend that it is going to be drop on correct.Dont assume that. The carb i pulled off the engine had damage so i gave you the one from in the barn. That means last time it was used it was mounted to a turbo...so..with it ebing leaned out and then being mounted to a turbo as a suck through probably means 1 of 2 things.

The original turbo setup had so many boost leaks that it was over fueling to the amount of air going into the engine (highly likely) and thats why it was leaned out

or 2 lean makes more power but also more damage. and thats why it was leaned out.

edit: while robbing it of parts and such

edit: while robbing it of parts and suchyour good.sorry, what I had meant by tuned was "not stock" jets that they ship with. thanks for clarifying, which you probably did before. I'm not trying to pretend that it is going to be drop on correct.

one of the secondary jets was so tight that it will need to be drilled out to remove, so it's staying there and i'm going to primarily mess with the carter, and use the edelbrock for messing with for future needs and knowledge.edit: while robbing it of parts and such

yeah everything i've found out is that edelbrock bought or licensed or whatever the carter designs, so everything crosses over between them. I'd bet the only minor differences between these is due to the years they were madeyour good.

I just read it as.

"its tuned for a running 400 and will work fine in this setup"

and i thought....

"the guy that owned this stuff before took a few turbos back from his deployment and slapped some shit on his old truck and it melted down i should say something"

Edit: carter should be a good choice. Not that familiar with them other than in the 3x2 setups. But they seem pretty stable. and IIRC a edelbrock carb is based on a carter. not 100% on that but edelbrock didnt make their own carb they closely followed someone elses design.

so i didn't have time to actually get any numbers from the stock setup

so i didn't have time to actually get any numbers from the stock setup

i'd still like to get a manual choke on there, but it is now very low priority. No idea what this plug was intented for, but if it's just going to dangle there, imma use it

i'd still like to get a manual choke on there, but it is now very low priority. No idea what this plug was intented for, but if it's just going to dangle there, imma use it

don't remember it in person, but hell, there it is in the picture. Wiring is so zany on this thing, even the wife was like "there is no way this truck is new or fancy enough to justify all these wires". I don't have time+desire for a while to tackle it, but damn will it be nice to redo all that stuff. Going to hack in whatever needs to happen to make the trailer lights work sooner rather than later

don't remember it in person, but hell, there it is in the picture. Wiring is so zany on this thing, even the wife was like "there is no way this truck is new or fancy enough to justify all these wires". I don't have time+desire for a while to tackle it, but damn will it be nice to redo all that stuff. Going to hack in whatever needs to happen to make the trailer lights work sooner rather than later what a damn mess of, just everything.

what a damn mess of, just everything.

and how you can arrive at leaning it out all over while thinking it is rich

and how you can arrive at leaning it out all over while thinking it is rich  pretty good read Trouble Tuning the Edelbrock Performer 1406 Carb? Read On...

pretty good read Trouble Tuning the Edelbrock Performer 1406 Carb? Read On...