Ford PMGR Starter Upgrade

PMGR is short for

Permanent

Magnet

Gear

Reduction. What exactly does that have to do with an upgrade? Well, it means that when retrofitting the older positive engagement starters it provides a 50% weight reduction (8 vs. 20) and requires less cranking amps. And because the PMGR starter is a smaller size, it provides better header clearance and reduces the effects of a hot start and your vehicle will be easier to jump start too. The only down side is that these starters do cost more than the old style starters.

I6 and V8 Applications (Small Block)

For

automatic transmissions, the Ford part numbers are E9SZ-11002-A, F7SU-11000-AB, F7SZ-11002-AA. Lester No's: 3205, 3268 (Retrofits Lester No's: 3124, 3153, 3168, 3180)

This part number will retrofit most small block 302/351W applications from 68-91.

For

manual transmissions, the Ford part numbers are F2TU-11000-AA, F2TZ-11002-A, F7PU-11000-FA, F7PZ-11002-FA. This part is used on 92-97 Ford Bronco, F Series 4.9L, 5.0L, 5.8L w/ MT. Lester No's: 3223, 3241 (Retrofits 3132, 3176, 3185).

Note: Manual transmission model made after 1979 may need Lester part #3205

John Johnson of the

Mustang II forum has amended and verified that the 75-78 Mustang II with 302 and 4 speed can use a 95 Mustang automatic starter Lester #3205. Thanx John!

This part number will retrofit most I6 221/240 and small block 260/289/302/351W from 62-79.

V8 460/ 351M

The starters used on 92-97 Ford E/F Series with 460 motors will also work as a higher torque upgrade mini starter on older 460 motors. Lester part no. 3226 upgrades on older 460 motors with automatic transmissions and Lester part no. 3225 upgrades older 460 motors with manual transmissions.

V6 Applications

This part number Lester part no's. 3204 will also work as a higher torque upgrade mini starter on most 86-91 Ford Taurus/Sable 3.0L/3.8L and 88 Lincoln Continental 3.8L

4 Cylinder Applications

Vehicles that use the PMGR starter Lester part no's. 3231 compatible with the 91-02 Ford Ranger 2.3L, 2.5L will also work as a higher torque upgrade mini starter on all older Ford 2.0L and 2.3L engines

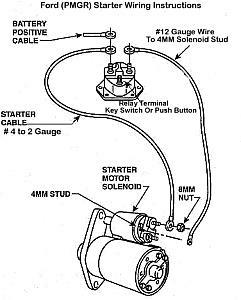

Installation and Wiring

Installation is actually pretty simple. After replacing the starter the rest is some simple wiring. On the starter solenoid, move the starter cable from its current location to the constant hot terminal (

where the battery cable hooks up). The new wire is a length of 12 gauge wire from the stud on the fender mounted unit where the starter cable formerly resided to the start terminal on the starter mounted solenoid. Just add the appropriate connector to each end of this new wire. The starter end connection could be either a 1/4 inch spade or a M6x1.0 post. The conversion is done!

WARNING - Do not install a jumper wire from the battery terminal stud to the solenoid activation stud on the starter in order to avoid installing the 12 gauge wire from the solenoid activation lug from the starter relay. This will cause the starter to stay engaged once the solenoid is activated. This will severely damage the starter and/or flywheel.

A couple of noteworthy functional differences with the new style starter

The

FIRST is that the starter seems to "run on" after the switch is released. This is an installation issue. This is a common complaint on Ford permanent magnet starters, although it can occur on any permanent magnet starter in the right conditions. This situation develops when the ignition terminal on the starter is "jumpered" to the battery terminal on the starter and a remote solenoid is used. Permanent magnet starters can actually produce power if they are driven from an outside source (i.e. the starter will act like an alternator once the engine fires and starts spinning). The current produced in the starter for this second or so will flow from the starter’s battery terminal to the starter’s ignition terminal and hold the solenoid in. This will cause the one to two second delay in the solenoid release and an irritating noise. The solution is to wire the starter per the instruction sheet, which will ensure that the ignition switch terminal goes dead the instance the key is released.

The

SECOND issue is that the pinion does not retract when it is released. It is normal for a gear reduction starter to hang in the ring gear when the engine is cranked, and yet does not start. Direct drive starters do not do this because they can rotate the small amount necessary to retract the pinion. Gear reduction starters do not retract in this situation because of the resistance of the gears. The tiny amount of rotation necessary to retract the pinion is amplified in the gear ratio inside the starter, requiring four to five times the rotation inside the starter. All of this gear movement results in the pinion remaining in the ring gear until the engine fires.

Reference Page Link -

CJ Pony Partshttps://bzerob.com/library/ford/ford-pmgr-starter-upgrade.html

The driver side was *close* to going in. I used the grinder to take down some casting nub on the bellhousing, beat a fairly sizeable area into one of the tubes, took off the trans support and lifted it up, dropped it down, all i ever got was *close*

The driver side was *close* to going in. I used the grinder to take down some casting nub on the bellhousing, beat a fairly sizeable area into one of the tubes, took off the trans support and lifted it up, dropped it down, all i ever got was *close*  oh well. also, either 1 of the 180* bends was lost in shipping or never put in the box, don't think i'll need it, don't care to file a dispute over it

oh well. also, either 1 of the 180* bends was lost in shipping or never put in the box, don't think i'll need it, don't care to file a dispute over it

had a whole bunch of interest, she was the first to actually show up with cash (after i added the second muffler, it was too loud for the general public before apparently)

had a whole bunch of interest, she was the first to actually show up with cash (after i added the second muffler, it was too loud for the general public before apparently)