desertPOS

Red Skull Member

- Joined

- Jul 2, 2020

- Member Number

- 2236

- Messages

- 339

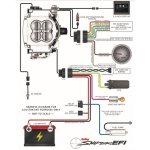

Trying to get my head wrapped around a plan for full rig wiring - thought I'd throw it up here and see if anyone has any feedback that might help dial things in. For now, mostly wanting to get main cables, bulkhead connectors and fuse boxes ordered so I can make sure I've got room for everything where I'm planning to put it - passenger side dash. Initial schematic that I'm sure will change:

1/2" firewall bulkheads at Del City only rated for 400 amps, so I need to find something heavier duty - think winch peaks out at 450 or 500 amps. Same with junction studs under the hood. Any problems with that plan? I like the idea of bulkheads and junction studs, since I can tee off from there for power to battery main switch, starter, etc. Although the alternative is running a cable solely for winch, pass-though firewall so no extra connections, then run separate cables for batt switch and underhood power. But then there's still the Premier Power Welder. Pros/cons?

For power distribution, I'm looking at stuff like this:

www.delcity.net

www.delcity.net

For 'fusebox 3' with close to 30 circuits/fuses it'd be great to find a power distribution box that can handle all of it together - especially if there are slots to plug in relays. Found this, which looks like a cool solution, but seems a little steep at $450

There's also the Busted Knuckle boxes that I don't quite understand the pricepoint on: 16 circuits Weatherproof Relay/Fuse Center

Good video showing Eaton fuse modules like linked above, with links to tools/parts needed:

Thoughts or critiques on random bullshit posted above? I ain't no electrical enginerd

.

1/2" firewall bulkheads at Del City only rated for 400 amps, so I need to find something heavier duty - think winch peaks out at 450 or 500 amps. Same with junction studs under the hood. Any problems with that plan? I like the idea of bulkheads and junction studs, since I can tee off from there for power to battery main switch, starter, etc. Although the alternative is running a cable solely for winch, pass-though firewall so no extra connections, then run separate cables for batt switch and underhood power. But then there's still the Premier Power Welder. Pros/cons?

For power distribution, I'm looking at stuff like this:

Metri-Pack 280 Sealed MINI®/MIICRO® Fuse & Relay Panel - 30 Amp, Bussed

ISO 280 Mini Relay - Bussed Inputs

For 'fusebox 3' with close to 30 circuits/fuses it'd be great to find a power distribution box that can handle all of it together - especially if there are slots to plug in relays. Found this, which looks like a cool solution, but seems a little steep at $450

Street / Strip Wiring Board 8 70amp Relays

Street/Strip wiring board features: 8x 70 amp relays with heavy duty fuse sockets (one with built in optional transbrake safety for use with nitrous system), fused transbrake relay. Fused lighting outputs including high beam headlights, low beam headlights, turn signal blinkers, brake light...

precisionfabandwire.com

There's also the Busted Knuckle boxes that I don't quite understand the pricepoint on: 16 circuits Weatherproof Relay/Fuse Center

Good video showing Eaton fuse modules like linked above, with links to tools/parts needed:

Thoughts or critiques on random bullshit posted above? I ain't no electrical enginerd

.